How 3D Printing Is Changing Auto Manufacturing

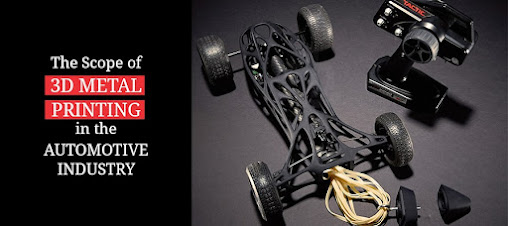

Car manufacturers have been using 3D printing to check form and fit as well as validate the operation of functional prototypes. For some full-size prototyping such as checking the fit of a rear-view mirror, affordable FFF / FDM technology can be used. For functional applications that require tougher parts or smoother finishes like mounts or aerodynamic components, resin & powder based technologies that can work with composites and nylons are preferred. Material jetting & 3D Inkjet is often used for full-color display models and miniatures.

Perhaps the second most popular use of 3D printing in the automotive space is fabricating manufacturing aids like jigs and fixtures. Making manufacturing tools using traditional means is rather costly and time consuming, and limitations on geometry translate into both less efficient manufacturing processes and more constraints on the geometry of end-use parts. Manufacturing tools that are 3D printed are lighter and more ergonomic, making it easier and safer for factory workers to perform their duties. That saves time and money on the factory floor.

Injection molds for plastic parts and casting cores for metal parts can also be 3D printed, allowing for more design freedom using traditional manufacturing methods and materials. Additionally, topographical optimization is becoming standard practice across the industry, where the geometry of parts is optimized to achieve the strongest shape while requiring the least amount of material. These algorithmic designs are generally more organic in their structure, which makes them difficult or impossible to produce without using 3D printing somewhere along the chain. GM, Volvo, Ford, and many others use 3D printing to produce manufacturing aids to save money, improve designs, and cut lead times. BMW even 3D printed an orthotic device that relieves thumb stress for their plant workers when they’re completing assembly tasks.

Fabricating End-Use Parts

Luxury and Custom Cars

Though production speed is steadily improving with AM, it’s still a bottleneck of the technology. The production volumes associated with automotive manufacturing are very high, tallying to hundreds of thousands of runs for every part. That would be difficult for most AM technologies to keep up with (for now). But many high-end automobile manufacturers limit the production runs of their cars to only a few thousand units, which makes AM a viable option. It doesn’t get more high-end than Rolls Royce, whose custom cars take so long to make that the company is actually using AM to increase production numbers. BMW has provided tens of thousands of components for the Phantom, such as buttons, parking brakes, and more. Other luxury car companies use 3D printing to customize interiors, including Bently, Porsche, BMW, and Ferrari.

Comments

Post a Comment